Our supreme unique design, philosophy and shape. (designed - built - test - produce @ 21/10/2009)

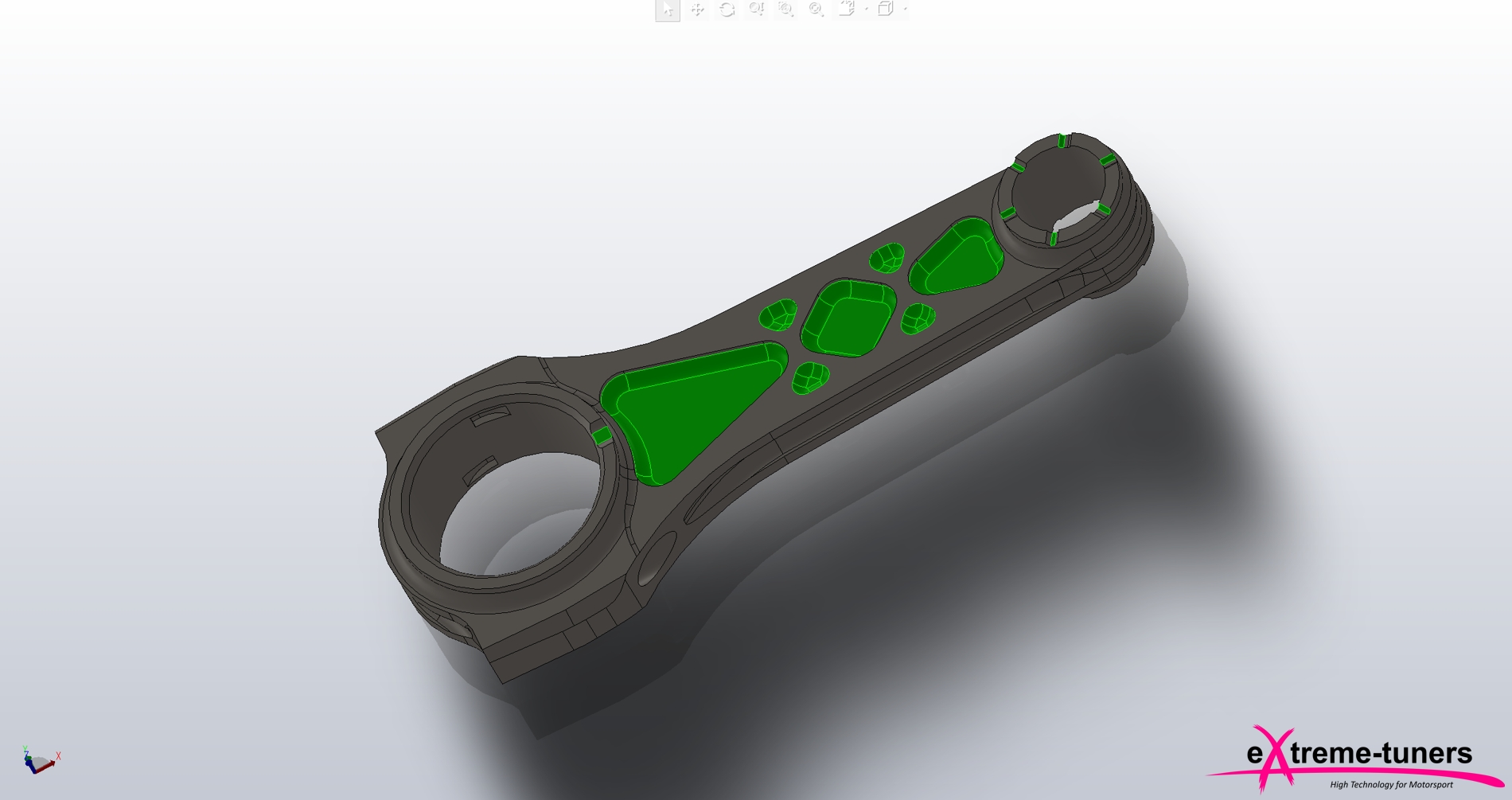

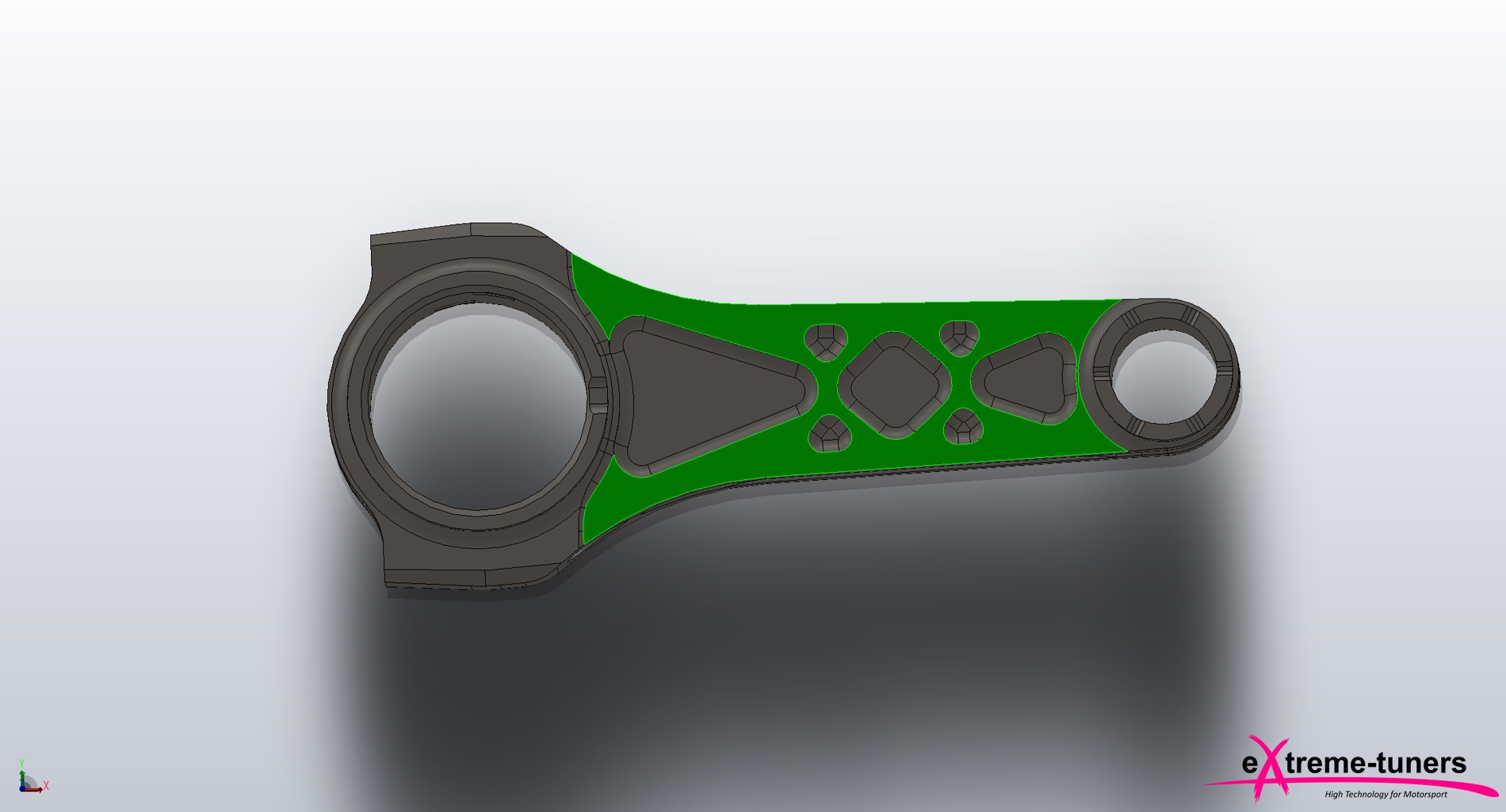

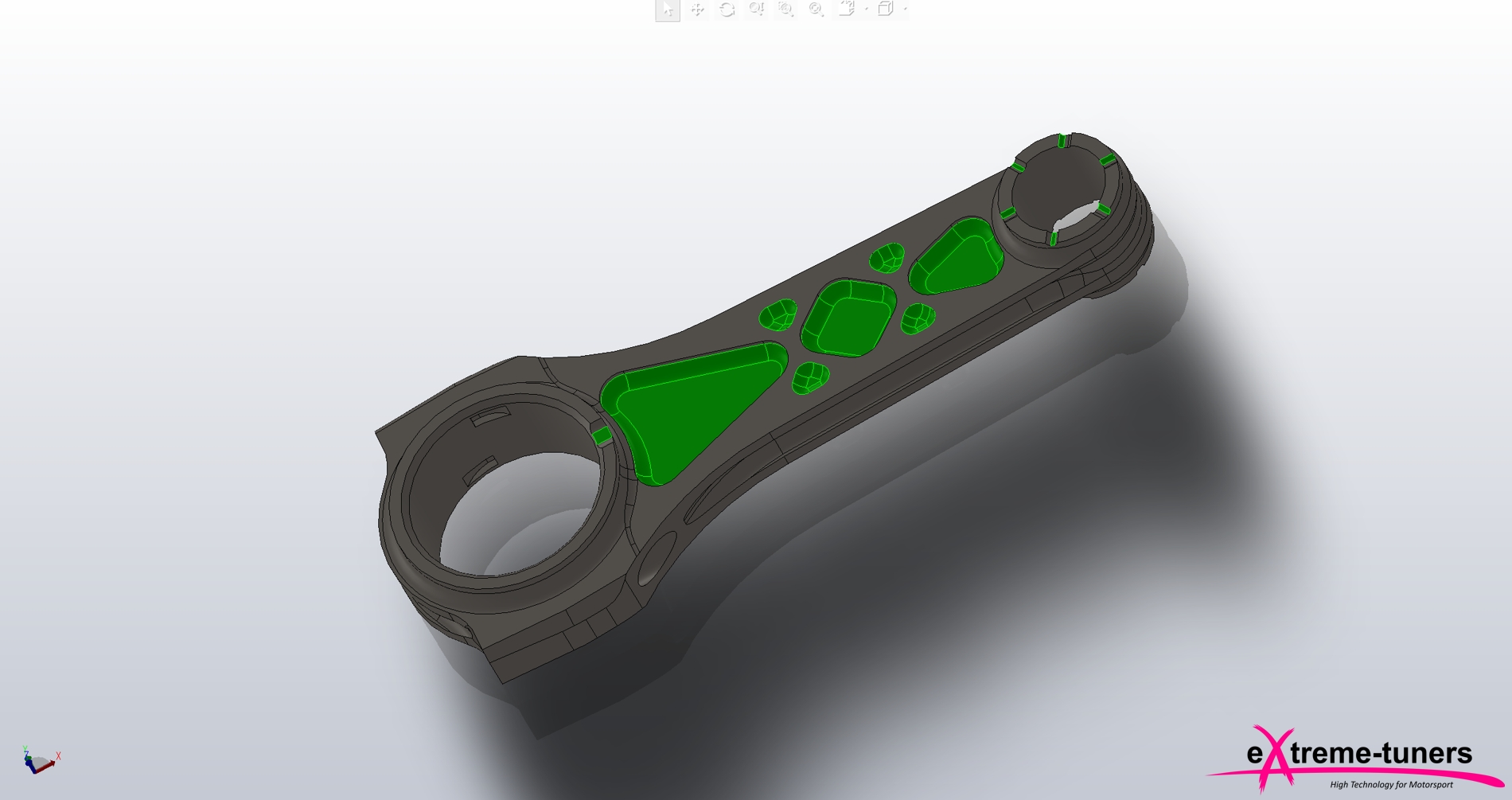

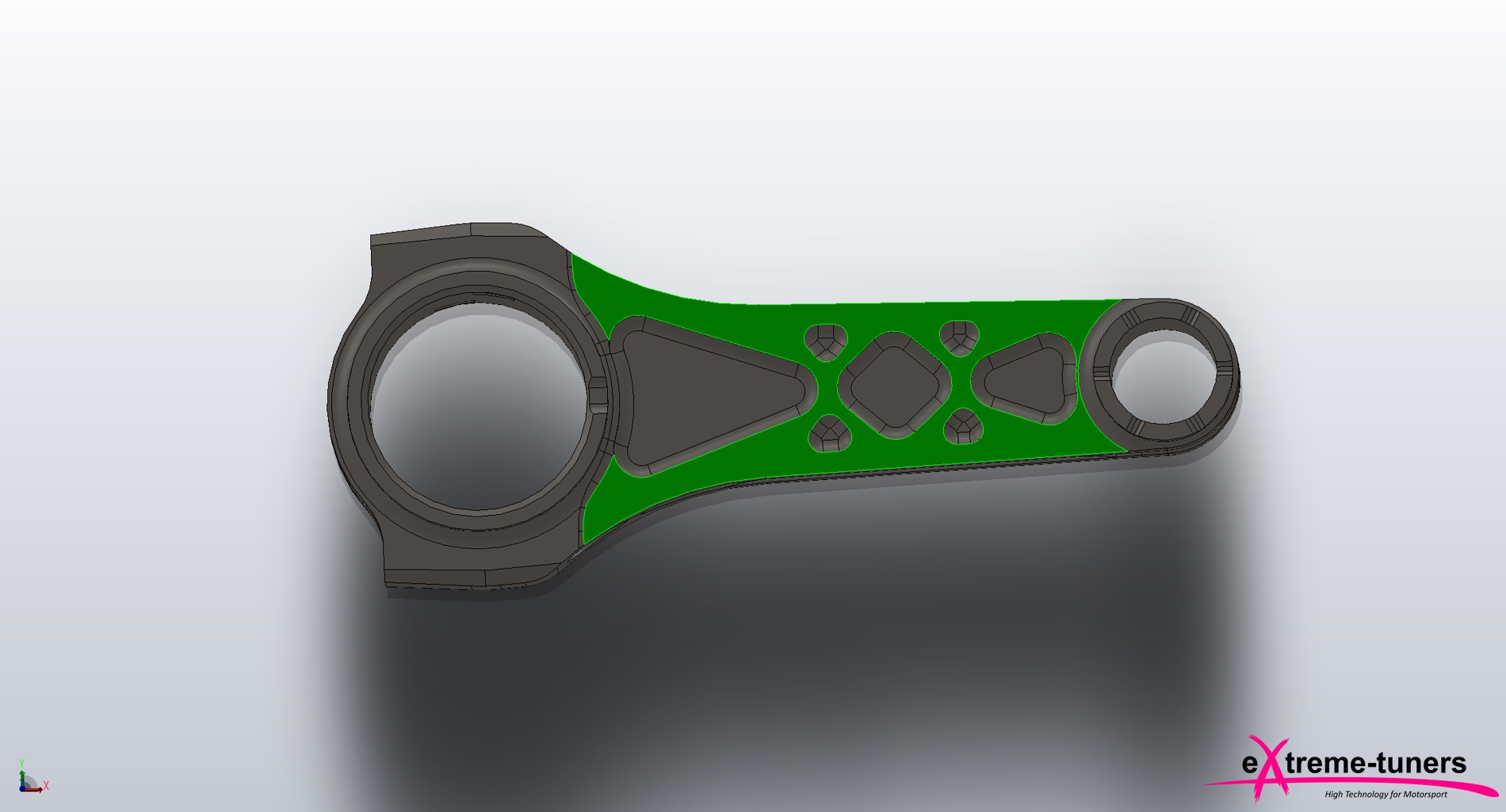

Envolving with F1, in 2009 as tecnology leaders we wanted to give to public the best design of rod can buy. After many hours of simulation and finite element analysis (FEA) to analyze the compression and tension forces & stress tests we invent the draft design of "pocket design". This design means that on the two large flat area surfaces on the rod we make small inner round & oval designs that offers ~38% more tension forces than "I" or "H" design, the center area may be machined to create a scalloped effect between the beams, leaving a rounded area next to both beams that increases strength and rigidity much like the filets on a crankshaft journal. Can handle high compressive loads while also providing good tensile strength, and have a thicker cross-section in critical areas to increase strength.

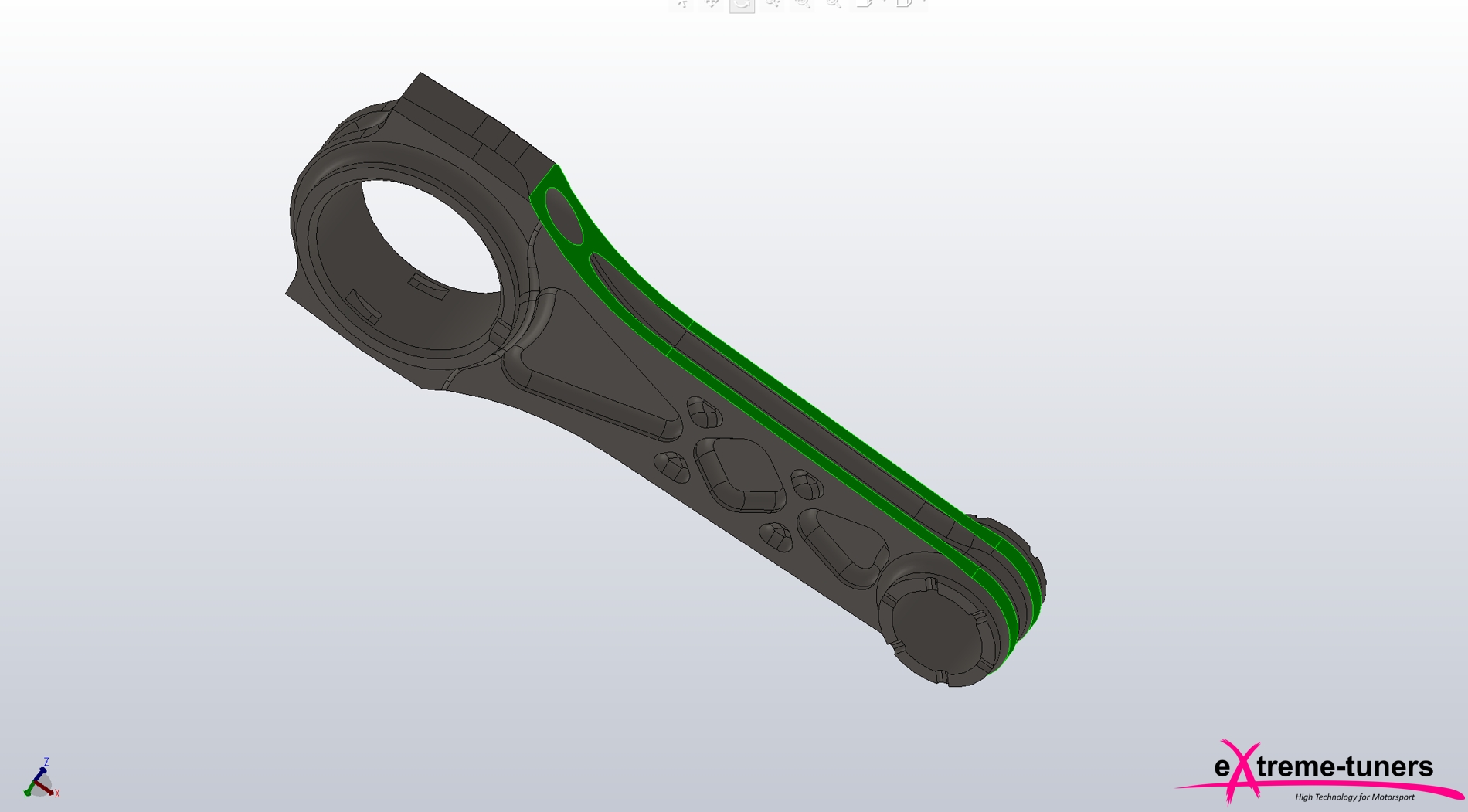

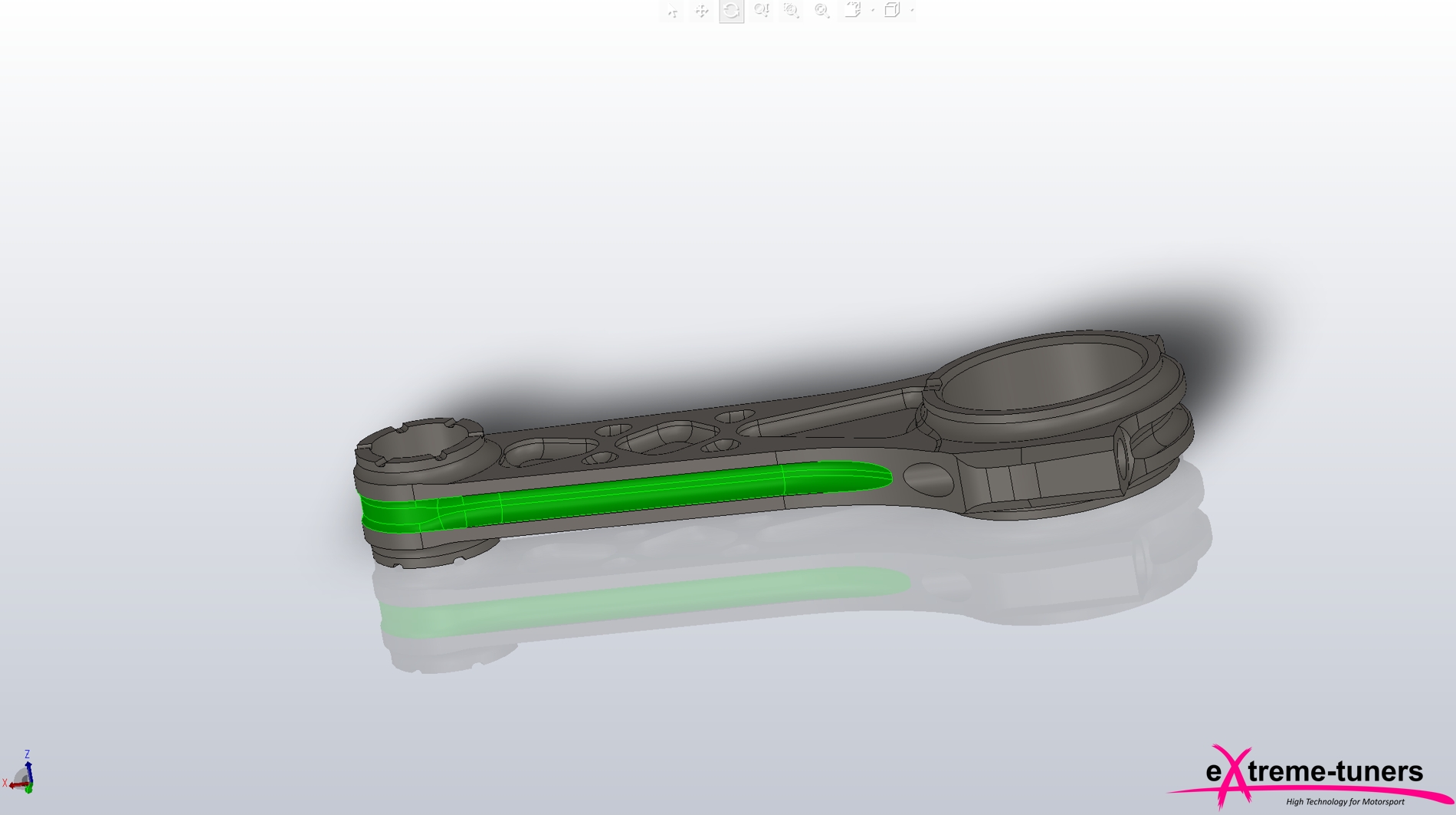

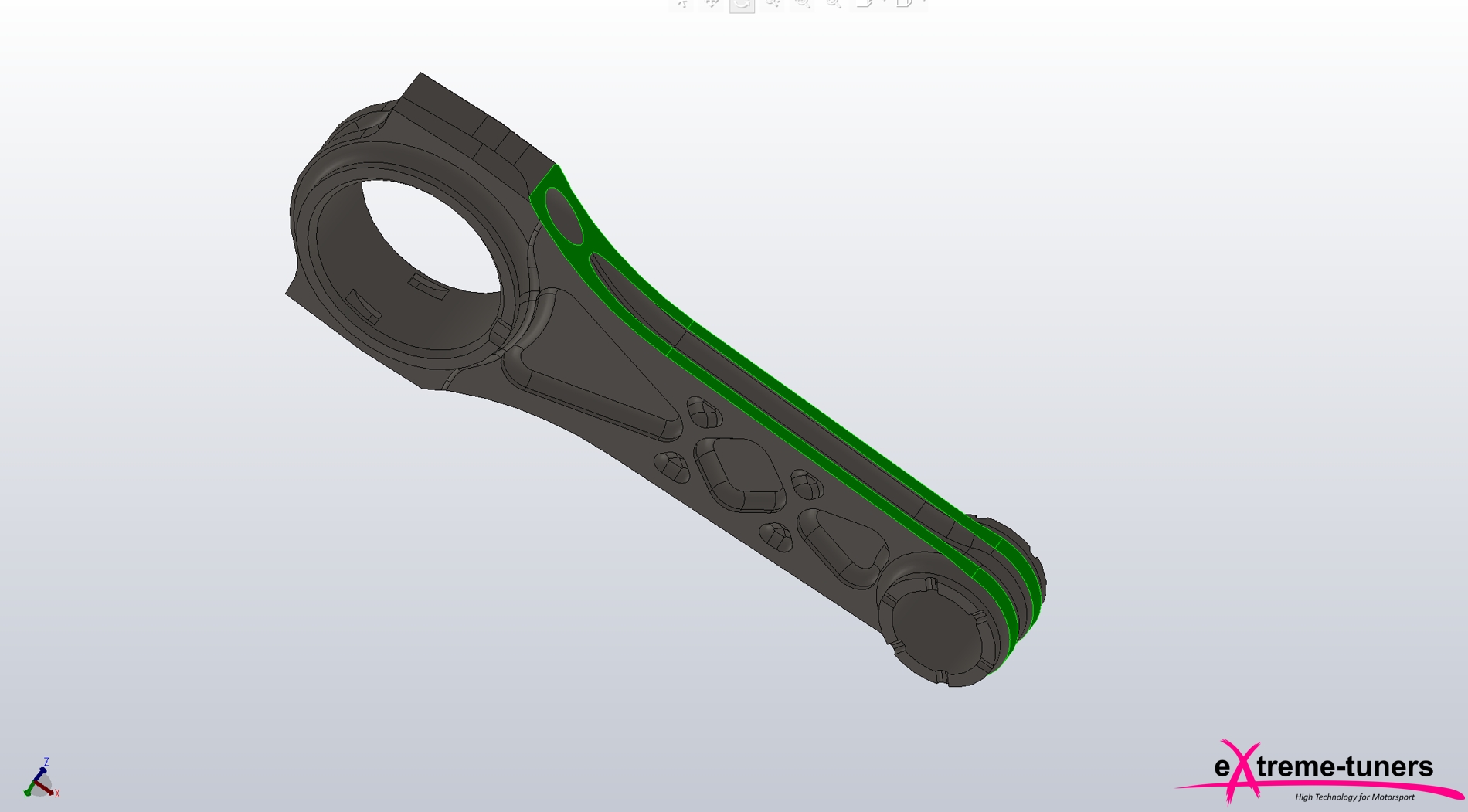

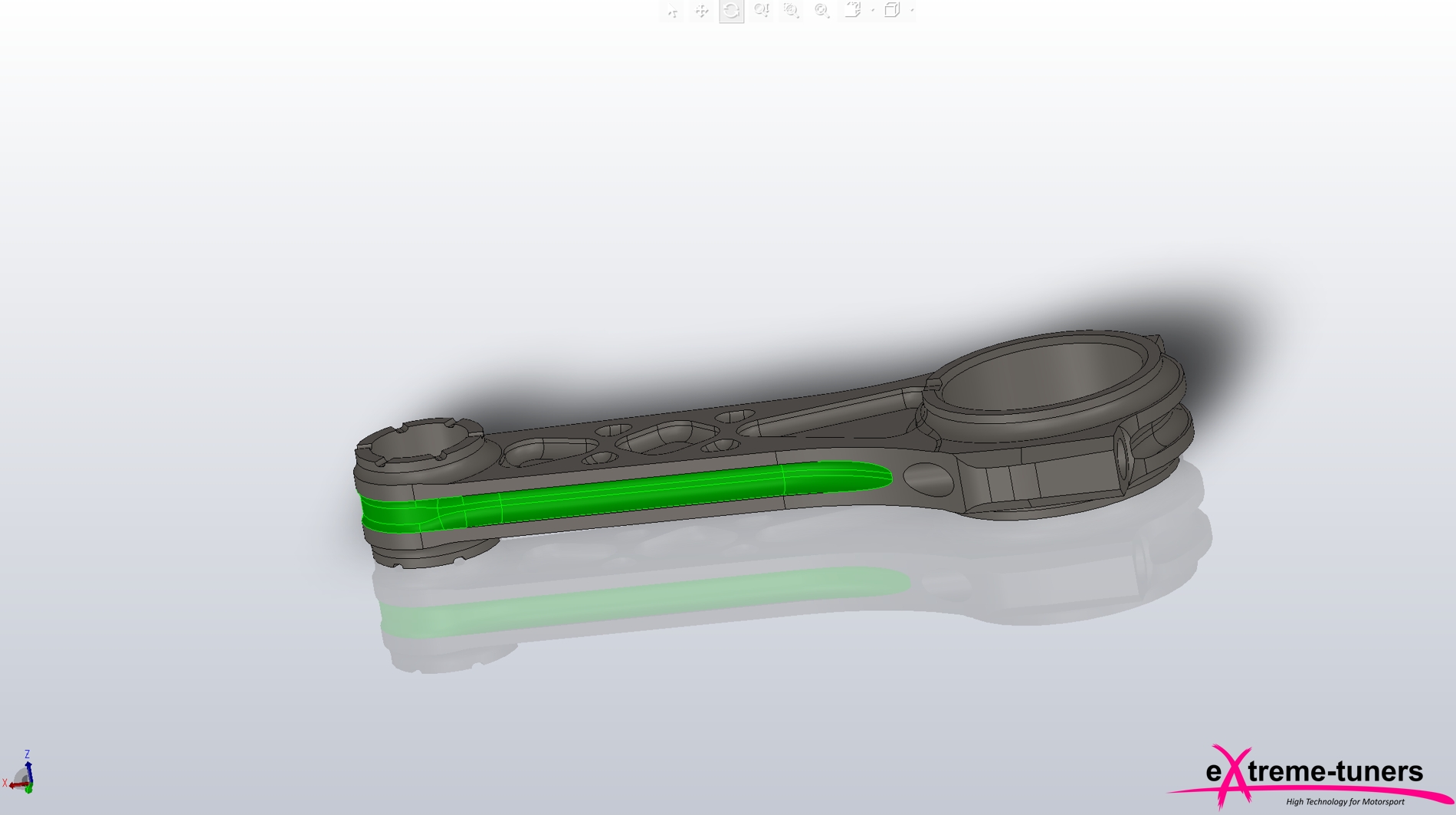

But not only the pocket design that makes our rods unique, as using only this design on the rod the rod may bend and fail if the compressive forces are too great. So to handle higher horsepower loads on the side beams of the connecting rods that are parallel to the holes in the ends for the piston and pin and crank journal, we built two flat side beams that are perpendicular to the piston pin and crankshaft journal bores. The center area that connects the two sides of the “H” together provides lateral (sideways) stiffness. This type of design can provide higher compressive strength with less weight than a comparable I-Beam.This makes the total design very stiff so it can handle higher compressive loads without bending.

Although this rod design is very dificult to construct and machine because wants special tooling and takes much longer time than the classic designs "I" or "H" beam. But we don not accept nothing less than the best.

Unique Pocket design

Combining "H" design

A large variety of connection rods, rod bolts and rod bushing is available for all famous engine types and brands.

We always have the option to produce any high-tech custom designed rods, according to customers’ demand.

When it comes to rod selection, which is more important: horsepower or rpm? Higher power levels increase the compressive force on the connecting rods while higher rpms increase the tensile strain on the rods. As it turns out, most rods don’t bend and fail on the compression stroke but are pulled apart at high rpm and break on the exhaust stroke. Consequently, rods need additional compression strength and stiffness to handle higher horsepower loads. But in hig- revving engines, increased tensile strength is an absolute must for the rods to survive at high rpm.

Below is our main types of materials, please send us email to help you.

Rod types in Billet forgings plate

Billet rods 2d 4340 steel material (no pocket design H or I beam) - 250hp per rod

Billet rods 2d 4340 steel material (pocket design) - 320hp per rod

Billet rods 2d tool steel material (pocket design) - 400hp per rod

Billet rods 2d Alu material (pocket design) - 350-400hp per rod

Billet rods 2d Titanium Ti6AL4V material (pocket design) - 350 - 400hp per rod

Billet rods 2d Aerospace custom alloy 970Mpa yield strength (pocket design) - 450 - 500hp per rod

Billet rods 3d tool steel material (pocket design) - 440hp per rod

Billet rods 3d Alu material (pocket design) - 450-500hp per rod

Billet rods 3d Titanium Ti6AL4V material (pocket design) - 400 - 450hp per rod

Billet rods 3d Aerospace custom alloy 970Mpa yield strength (pocket design) - 650 - 700hp per rod

* Please see at the bottom of the page our categories

Billet cnc built high quality rod bolts

Billet steel Alloy - 9000rpms 25m/sec

Billet H11 tool steel - 11000rpms 32m/sec

Billet H13 tool steel - 13500rpms 43m/sec

* Please visit our Rod bolt section

Beryllium upgrade Connecting Rod Bushings

* All parts are produced from real billet iso certified EU alloys.

* All our products are ISO 9001 certified.